Used Cooking Oil Transfer Caddies

C4G1 and C4G2 are the perfect solution for used cooking oil transfer. No more messy outdoor receptacles. No more fines from city inspectors for dirty trash corrals. On-site training. Total ease of installation and operation. A standard fryer can be pumped in approximately 60 seconds. This unit has wheels and can be rolled into place easily. This feature greatly reduces potential burns often caused by manually draining & transporting, protecting your employees and greatly reducing the potential for workers compensation claims due to safety aspects.

Equipment Overview

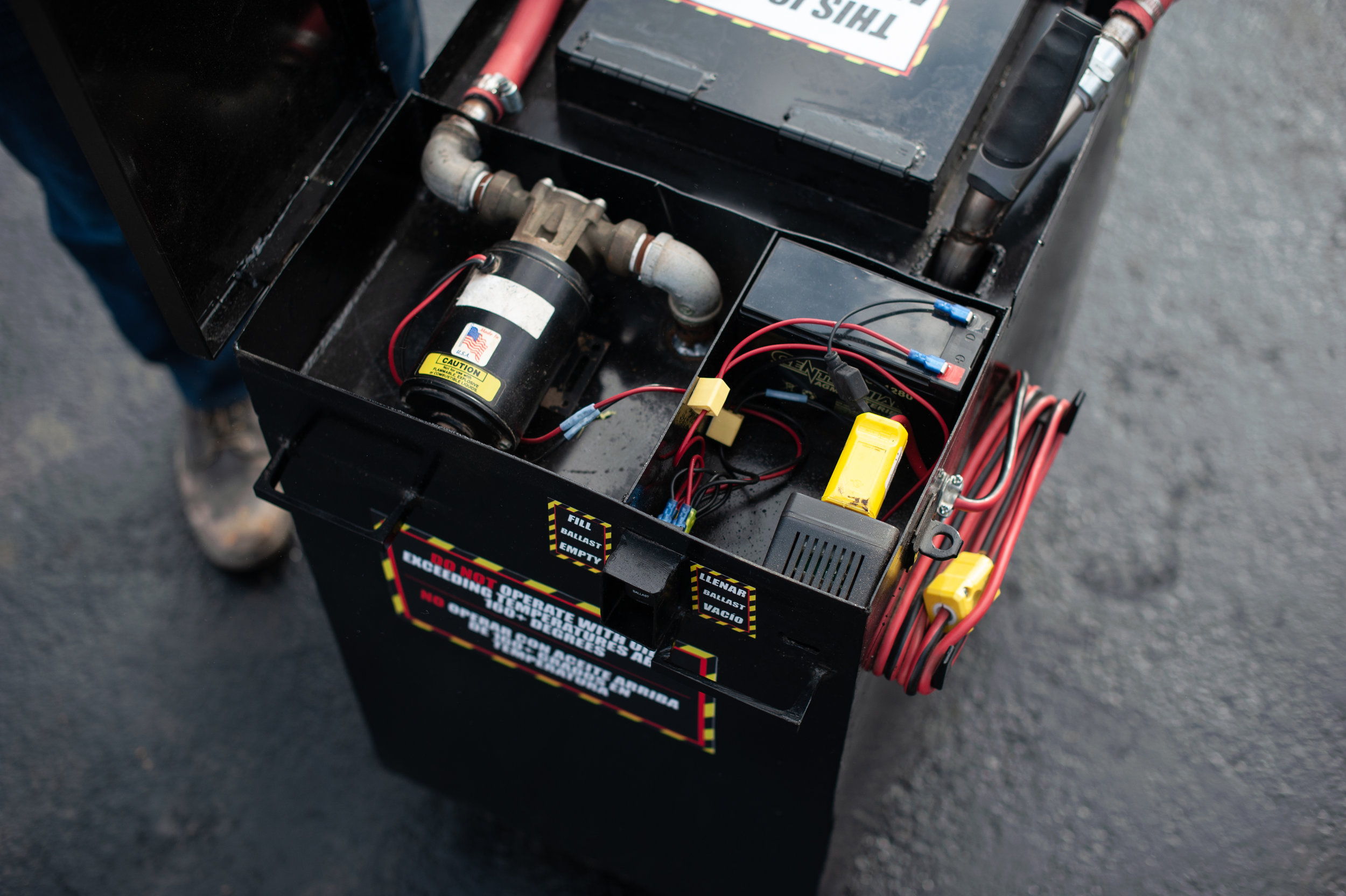

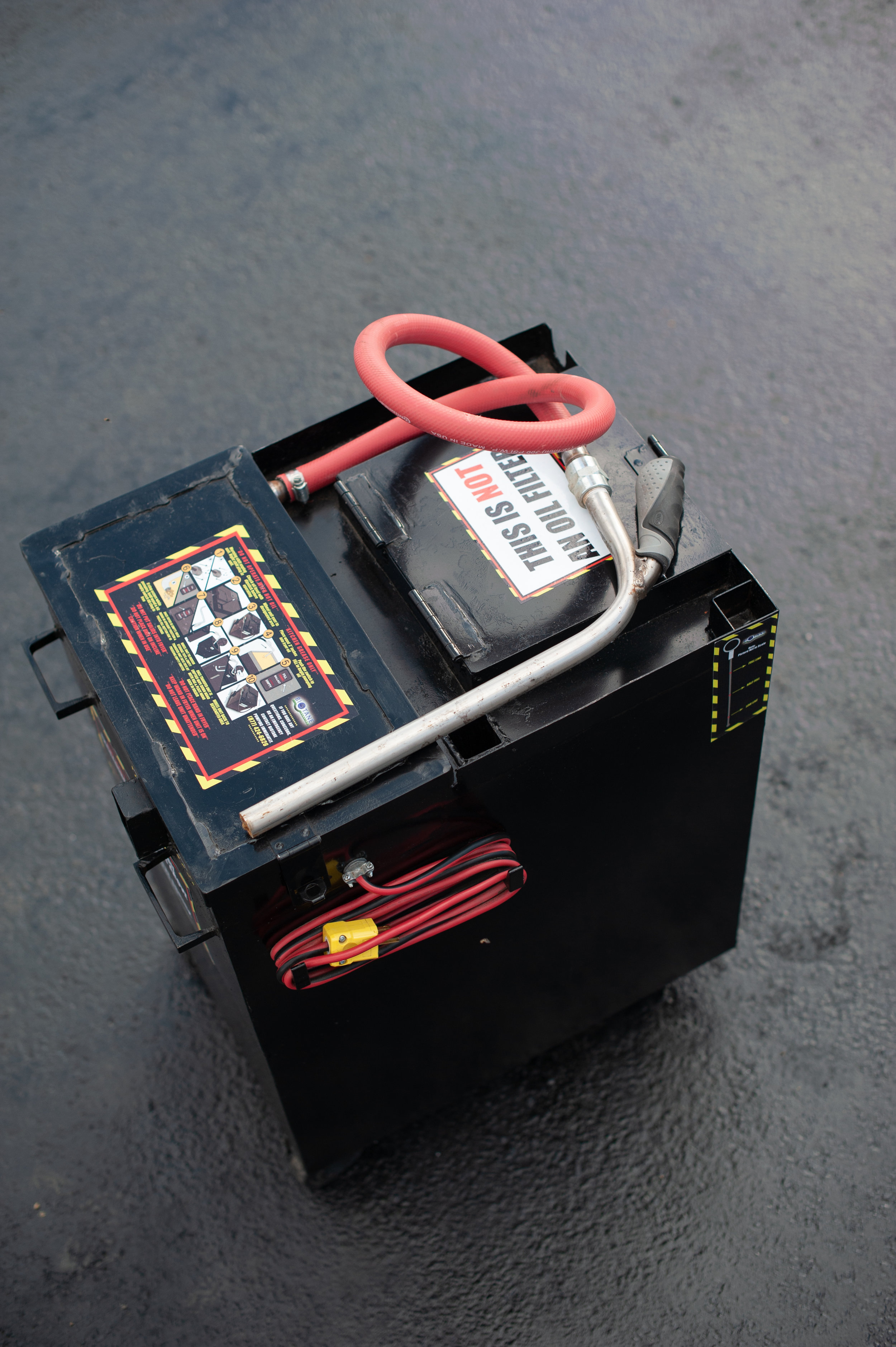

c4g1

Battery powered for unrestricted mobility

Two way pump fills and empties caddie

Compact design

Lockable and secure

Can store and transfer up to 40 gallons

Measurements:

Height 33.25”

Length 23”

Width 23”

Equipment Overview

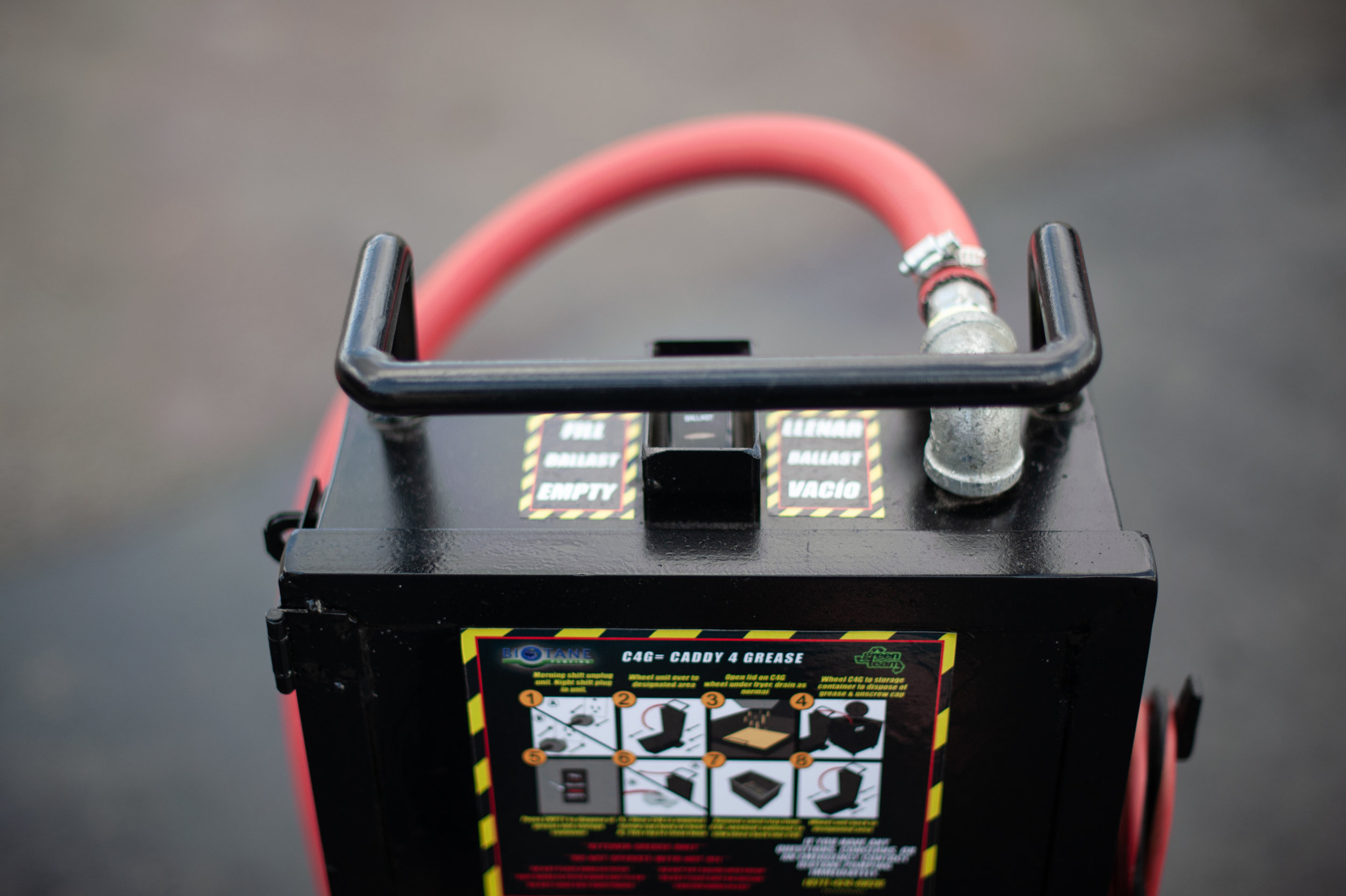

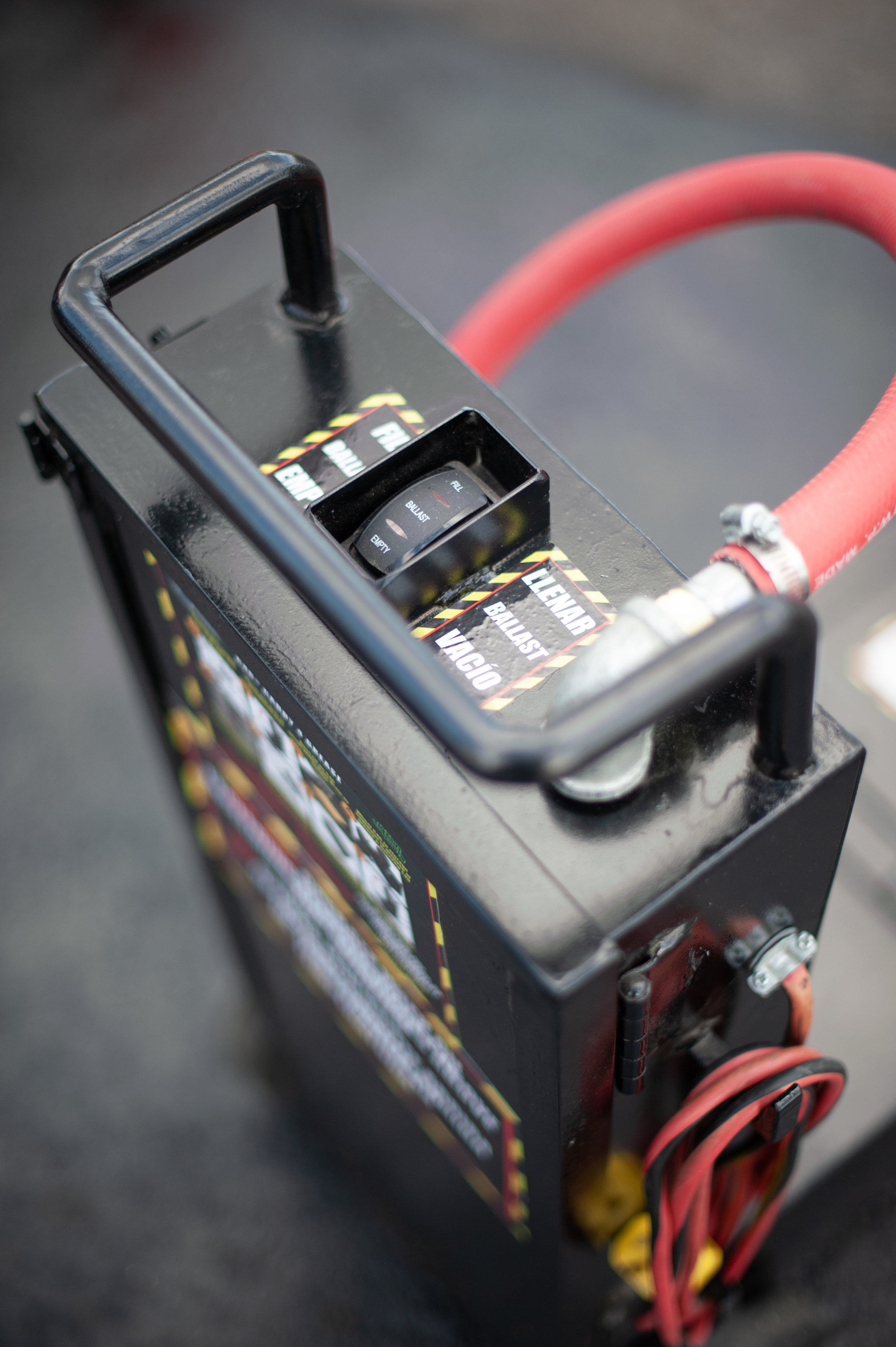

c4g2

Battery powered for unrestricted mobility

Two way pump fills and empties caddie

Compact design to fit under fryers

Catch Tray to filter out solids

Lockable and secure

Measurements:

Height 36”

Length 14”

Width 12”

Reducing Risk

The handling of used cooking oil from a kitchen fryer to a storage container presents a number of major safety and cleanliness concerns. Both the C4G1 and C4G2 model grease caddies were designed with employee safety and cleanliness as our top priority.

Cooking oil ranges in temperature from 350 to 375 degrees while frying, and could cause third degree burns if it comes in contact with someone’s skin. These caddies greatly reduce the potential for burn accidents often caused by manually draining & transporting used cooking oil. The catch tray on the C4G2 and the service wand on the C4G1 allow staff to easily remove the cooking oil from the fryer, while greatly decreasing the chance of a burn by coming in contact with hot oil.

Slips and falls are also a major safety concern in addition to burns when dealing with the transferring of used cooking oil. Cooking oil left on the ground after being spilled can create a slip and fall hazard for both employees and customers that could later result in a costly lawsuit or workers’ compensation claim. The C4G models minimize the risk of spillage by being designed to meet the need of your fryer.

Traditional fryers drain from the bottom, and employees often make a mess by trying to stick a bucket or used oil jug under the fryer to catch the cooking oil. The C4G2 was designed to slide under a standard fryer and line the catch tray up with the release valve on the bottom of the fryer. Once the oil is finished draining from the fryer, the employee can shut the catch tray door and simply wheel the caddy back out.

Other fryers have to be emptied from the top because they do not have access to their drain valve or have a specialized fryer set up. For those types of fryers the service wand on the C4G1 allows employees to extract cooking oil from the top of the fryer minimizing the risk of burn or spillage.

The spillage of transferred cooking oil can not only result in slips and falls but also cleanliness issues that could result in fines or shutdown of your business. These caddies mitigate cleanliness issues by using a battery powered two way pump to move the oil both in and out of the container. By controlling the flow of oil out of the caddy into your storage container, you reduce the risk of spills and preserve a clean work environment.